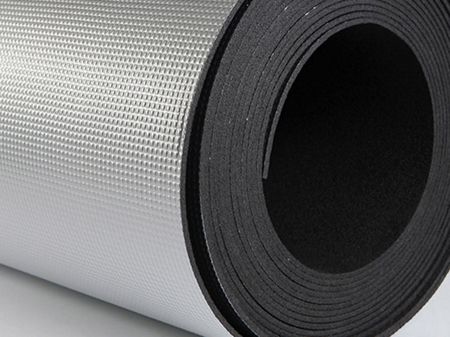

Aluminum Foil XPE Foam

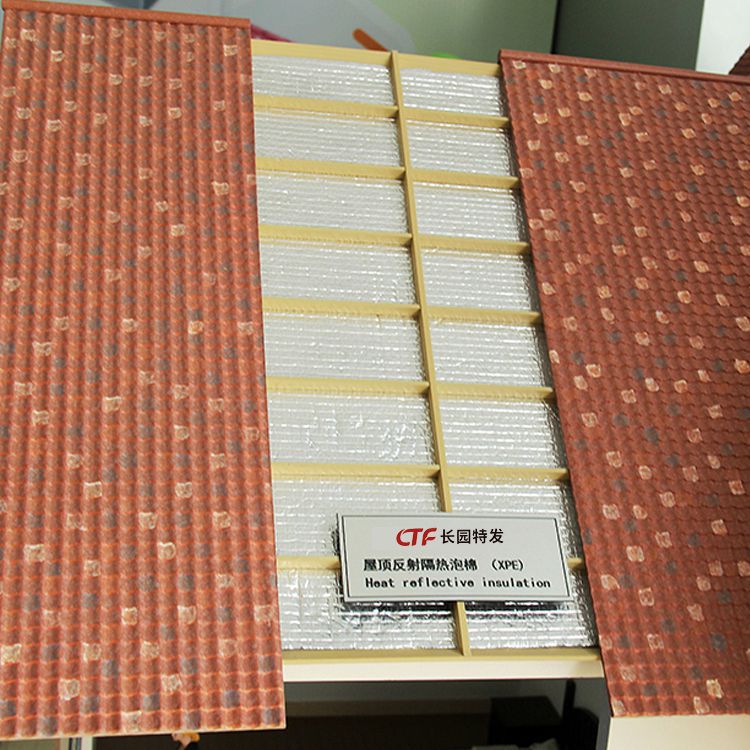

Aluminum foil XPE foam is a newly developed thermal and acoustic insulation material made from cross-linked polyethylene foam (XPE foam) covered with pure reinforced aluminum foil or aluminum coated film on both sides. The XPE foam as the base material has numerous characteristics of high tensile strength and tear resistance, and it is well suitable for applications requiring insulation materials with properties of thermal insulation, sound proofing, low water absorption, weather durability, chemical resistance and aging resistance. Pure aluminum foil is used as skin laminated to the XPE foam, providing reflective surface, corrosion resistance as well as good heat insulation. Our aluminum foil XPE foams are widely used as reflective insulation material for construction of industrial, commercial and residential building.

Features

- Strong moisture barrier, heat insulation, sound proofing, energy saving

- High tensile strength, superior tear resistance

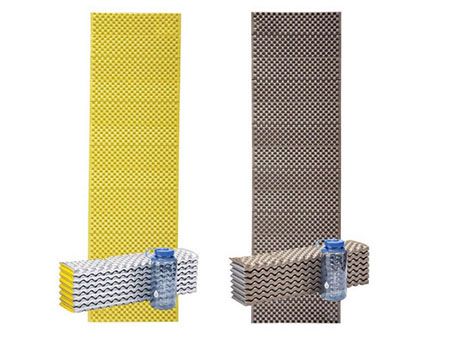

- Lightweight, flame retardant, easy to cut and install

- Odorless, environmentally friendly

- Low thermal conductivity, excellent thermal insulation

- Keep building warm in winter and cool in summer

- Material: XPE + pure aluminum foil (or aluminum coated film)

- Structure: aluminum foil + XPE + aluminum foil/ aluminum foil + IXPE + aluminum foil (or customized, e.g. woven fabric aluminum foil)

- Foam density: 30B (33kg/m³)

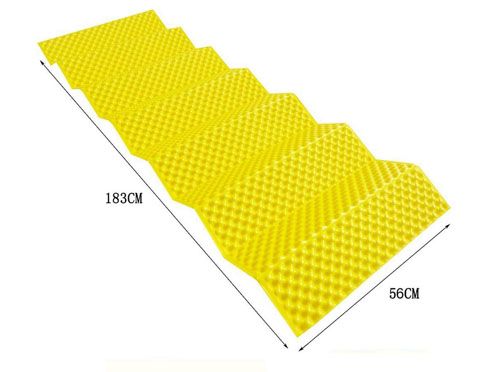

- Dimensions: 4mm×1350mm×40mts (or customized)

- Thickness: single layer 3-15mm, multi-layer 15-200mm, available in self-adhesive backing on one side

- Flame retardant: UL94 HF-1, GB8624-B1

- Color: grey, black, white

Technical Data

| Property | Standard | Unit | Value | |

| Density | - | Kg/m3 | 33.33 | |

| Tensile strength | Transverse | ISO-1798 | MPa | 0.25~0.27 |

| Longitudinal | 0.31~0.32 | |||

| Elongation | Transverse | ISO-1798 | % | 137.40~141.20 |

| Longitudinal | 159.70-166.00 | |||

| Tearing strength | Transverse | ISO-8067 | Kn/m | 1.28~1.33 |

| Longitudinal | 1.38~1.40 | |||

| Compression 25% | ISO-3386-1 | kPa | 36.40 | |

| Compression 40% | ISO-3386-1 | kPa | 62.40 | |

| Compression 50% | ISO-3386-1 | kPa | 95.20 | |

| Compression set 25% 0.5H | ISO-1856 | % | 19.10 | |

| Compression set 25% 24H | ISO-1856 | % | 4.10 | |

| Operating temperature range | Internal | ℃ | (-40~+80) | |

| Water absorption % volume(maximum) | Internal | % | 0.50 | |

| Thermal conductivity | JISA1412-2 | W/mK | 0.032 | |

| Shore- C | ASTM D2240 | ℃ | 22 | |

If you have questions about our products or want to request a quotation, please feel free to contact us at any time.

As an experienced manufacturer of heat shrink tubing and non-shrink tubing, WOER has a clear understanding of the industries requiring tubing and sleeving products used for electrical insulation, cable identification, wire bundling, environmental sealing and electronic component protection purposes. Whether you need electrical insulating tubing, wire harness tubing, heat shrink cable accessories, or other electrical application tubing products and cable identification products, we are a qualified source for your needs of heat shrinkable tubing products. WOER also provides superior value-added services such as cutting, printing and packaging to save your time and cost, so you can get your heat shrink tubes custom cut, printed and packaged.