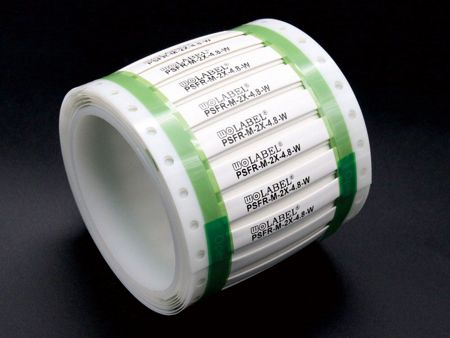

Cable Identification Tag

(Ladder Style)

Model: TAG

Our ladder style cable identification tag is made of eco-friendly cross-linked polyolefin. These identification tags are ideal for identifying cables and wire bundles with a wide diameter range in railway, subway, nuclear power station, aerospace and other applications having requirements for permanently legible marking.

The cable identification tags can be simply attached to cables and wire bundles by means of cable ties after being removed from the carrier. It is recommended to use thermal transfer printer and WO-80500BK thermal transfer ribbon to satisfy the SAE AS 81531 and MIL-STD-202F printing standards.

Standard

ASTM 2671/ DIN 5510-2

Features- Side entry allows for accessing to large size wire bundles, and offering the capability for retrofitting and repairing

- High flame retardancy, low smoke density emission

- Excellent resistance to abrasion, mechanical damage, fluids, lubricants and solvents

- Computer-printable, with any characters and logo design

- No melting at high temperature, no brittle in freezer

- Recommended printer: thermal transfer printer (WO-III-170/300DPI/WO-III-110/600DPI)

- Recommended ribbon: thermal transfer ribbon, 100mm×300m (WO-90984BK/WO-80500BK)

- Color: white, yellow, other colors are available upon request

| Order Code | Pack Size (pcs/coil) | Marker High (mm) | Marker Length (mm) | Printable Range (mm) | Recommended Use Range (mm) | |

| high | length | |||||

| DIN-M-4H-10.4- 45- 2K-W-B-P1-× | 2000 | 10.4 | 45 | 6.4 | 25 | 5.08~12.7 |

| DIN-M-4H-10.4 -53- 2K-W-B-P1-× | 2000 | 10.4 | 53 | 6.4 | 33 | 5.08~12.7 |

| DIN-M-4H-10.4 -64- 2K-W-B-P1-× | 2000 | 10.4 | 64 | 6.4 | 44 | 5.08~12.7 |

| DIN-M-6H-10.4 -76- 2K-W-B-P1-× | 2000 | 10.4 | 76 | 6.4 | 56 | 5.08~12.7 |

| DIN-M-6H-10.4 -90- 2K-W-B-P1-× | 2000 | 10.4 | 90 | 6.4 | 70 | 5.08~12.7 |

| DIN-M-4H-12.0 -102- 2K-W-B-P1-× | 2000 | 12.0 | 102 | 8.0 | 82 | 12.7~19.1 |

| DIN-M-4H-15.0- 45-1.5K-W-B-P1-× | 1500 | 15.0 | 45 | 11.0 | 25 | 12.7~19.1 |

| DIN-M-4H-15.0 -53-1.5K-W-B-P1-× | 1500 | 15.0 | 53 | 11.0 | 33 | 12.7~19.1 |

| DIN-M-4H-15.0 -64-1.5K-W-B-P1-× | 1500 | 15.0 | 64 | 11.0 | 44 | 12.7~19.1 |

| DIN-M-6H-15.0 -76-1.5K-W-B-P1-× | 1500 | 15.0 | 76 | 11.0 | 56 | 12.7~19.1 |

| DIN-M-6H-15.0 -90-1.5K-W-B-P1-× | 1500 | 15.0 | 90 | 11.0 | 70 | 12.7~19.1 |

| DIN-M-4H-20.3 -45- 1K-W-B-P1-× | 1000 | 20.3 | 45 | 16.3 | 25 | 19.1~25.4 |

| DIN-M-4H-20.3 -53- 1K-W-B-P1-× | 1000 | 20.3 | 53 | 16.3 | 33 | 19.1~25.4 |

| DIN-M-4H-20.3 -64- 1K-W-B-P1-× | 1000 | 20.3 | 64 | 16.3 | 44 | 19.1~25.4 |

| DIN-M-6H-20.3 -76- 1K-W-B-P1-× | 1000 | 20.3 | 76 | 16.3 | 56 | 19.1~25.4 |

| DIN-M-6H-20.3 -90- 1K-W-B-×-P1-× | 1000 | 20.3 | 90 | 16.3 | 70 | 19.1~25.4 |

| DIN-M-4H-25.4 -45- 1K-W-B-×-P1-× | 1000 | 25.4 | 45 | 21.4 | 25 | 25.4 and up |

| DIN-M-4H-25.4 -53- 1K-W-B-×-P1-× | 1000 | 25.4 | 53 | 21.4 | 33 | 25.4 and up |

| DIN-M-4H-25.4 -64- 1K-W-B-×-P1-× | 1000 | 25.4 | 64 | 21.4 | 44 | 25.4 and up |

| DIN-M-6H-25.4 -76- 1K-W-B-×-P1-× | 1000 | 25.4 | 76 | 21.4 | 56 | 25.4 and up |

| DIN-M-6H-25.4 -90- 1K-W-B-×-P1-× | 1000 | 25.4 | 90 | 21.4 | 70 | 25.4 and up |

| Property | States | Performance | Test Method |

| Tensile strength (MPa) | Unaged | ≥10.3 | ASTM D2671 |

| Heat-aged× | ≥6.9 | ||

| Ultimate elongation (%) | Unaged | ≥200 | |

| Heat-aged× | ≥100 | ||

| Voltage withstand (V) | Unaged | 2500 V,60s,Pass | UL224 |

| Dielectric strength (MV/m) | Unaged | ≥19.7 | ASTM D2671 |

| Heat-aged× | ≥15.8 | ||

| Volume resistivity (Ω-cm) | Unaged | ≥10^14 | ASTM D2671 |

| Water absorption (%) | Unaged | ≤1.0 | ASTM D 570 |

| Corrosion | Unaged | Pass | UL 224 |

| Heat shock | Unaged | No cracks, flowing or dripping | UL 224 |

| Low temperature flexibility | Unaged | No cracks | UL 224 |

| Flammability | Unaged | S3 Class | DIN 5510-2 |

If you have questions about our products or want to request a quotation, please feel free to contact us at any time.

As an experienced manufacturer of heat shrink tubing and non-shrink tubing, WOER has a clear understanding of the industries requiring tubing and sleeving products used for electrical insulation, cable identification, wire bundling, environmental sealing and electronic component protection purposes. Whether you need electrical insulating tubing, wire harness tubing, heat shrink cable accessories, or other electrical application tubing products and cable identification products, we are a qualified source for your needs of heat shrinkable tubing products. WOER also provides superior value-added services such as cutting, printing and packaging to save your time and cost, so you can get your heat shrink tubes custom cut, printed and packaged.